Our Products

Screen Printing Chemicals

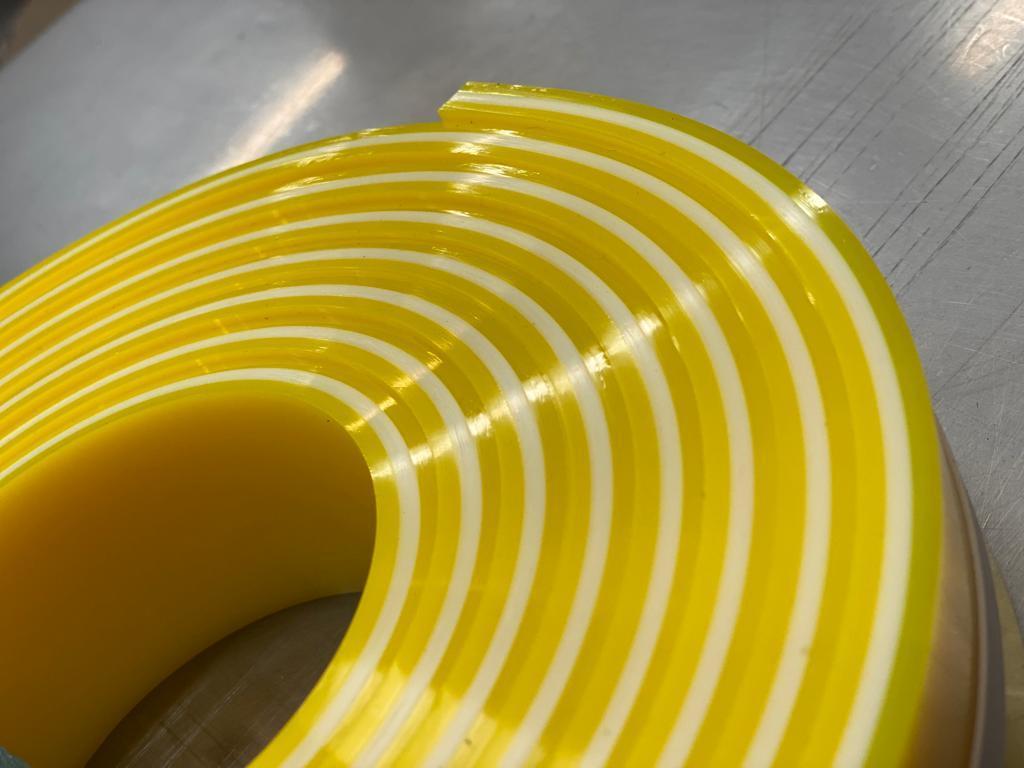

Serigrafi ve Filtre

Screen printing chemicals are various chemical compounds used in the screen printing process. These chemicals are used in different stages such as applying screen printing inks, preparing printing screens, surface preparation, and cleaning. Here are some examples of screen printing chemicals:

- Emulsion: Emulsion is one of the most important chemicals used in preparing the printing screens for screen printing. It is used as a photosensitive coating and forms the stencil of the print design. Emulsion is applied to the screen printing mesh, dried, and exposed to light to create the print pattern on the screen.

- Emulsion Remover: It is a chemical used to remove damaged emulsion after the printing process is completed. Emulsion remover is applied to the screen and left for a certain period. Then, it is washed with water or special cleaning solutions to completely remove the emulsion from the screen.

- Screen Cleaner: Screen cleaners are cleaning chemicals used to unclog the screen during the screen printing process. They are designed not to harm the screen mesh, ink, or emulsion while effectively removing clogs that occur on the screen during printing.

- Screen Adhesive: Screen adhesives are usually dual-component adhesives that ensure seamless bonding between the screen and the frame. They are developed to withstand solvents, UV, and water-based inks. Screen adhesives exhibit resistance to pressure during printing or exposure to solvents during or after printing. They are specifically formulated for this production system.

- Solvents: Solvents are chemicals used for cleaning or thinning solvent-based inks used in screen printing. Solvents are used to dissolve or dilute the ink. Solvent-based screen printing inks are cleaned using chemical solvents and can be diluted with solvents for fine adjustments.

These are just some examples of screen printing chemicals, and there may be more chemical substances used in different stages of the screen printing process.