Our Services

Screen Stretching

Serigrafi ve Filtre

Screen stretching is a service in the screen printing process that involves preparing the printing screens. This service ensures proper tensioning of the screen, leading to the desired quality of the print.

- Mesh Selection: The first step is selecting the appropriate mesh and mesh count.

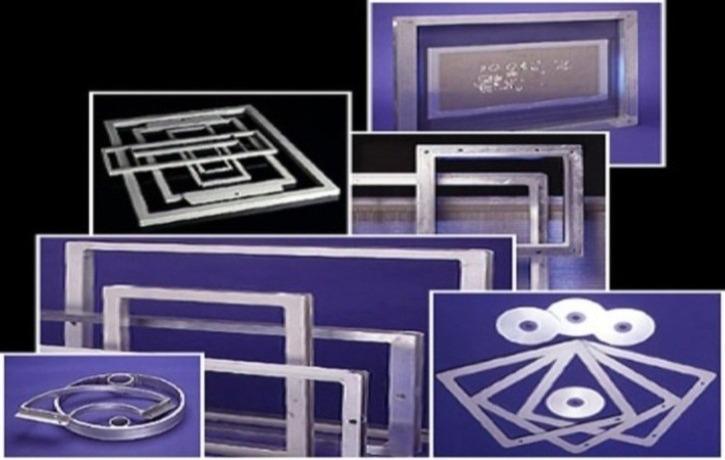

- Frame Preparation: Screen stretching requires stretching the mesh onto a frame. Therefore, preparing the frame is important. Aluminum, wooden, or iron frames can be used.

- Placement of the Mesh: The mesh is placed onto the frame according to the project's requirements and cut to fit the frame size. Proper mesh placement and creating the correct tension angle prevent unwanted deformations, scratches, and printing errors during the printing process.

- Screen Stretching: The screen is stretched onto the frame using a screen stretching machine or manual tools. A screen stretching machine ensures the screen is stretched evenly and to the desired tension level. If using manual tools, care must be taken to stretch the screen carefully and uniformly.

- Tension Control: After stretching the screen, the tension level is checked. This process should be done using a tension meter. If necessary, the tension can be further adjusted to ensure the screen is fully stretched. This allows the screen to function properly during the printing process and ensures clear and sharp transfer of the desired design.

Screen stretching service is important in screen printing to achieve proper tensioning of the printing screens. A well-executed screen stretching process reduces screen deformations during printing, resulting in sharper and clearer print outcomes. This ensures high-quality prints and consistency.